Harbinger, a California-based manufacturer of medium-duty electric vehicle (EV) platforms, has officially entered the production phase for its American-made electric stripped chassis, marking a milestone that could carry implications for stakeholders in the recreational vehicle (RV) and specialty vehicle markets.

According to a press release, the company confirmed it has manufactured more than 100 units and is now actively delivering to customers, including RV manufacturing giant THOR Industries.

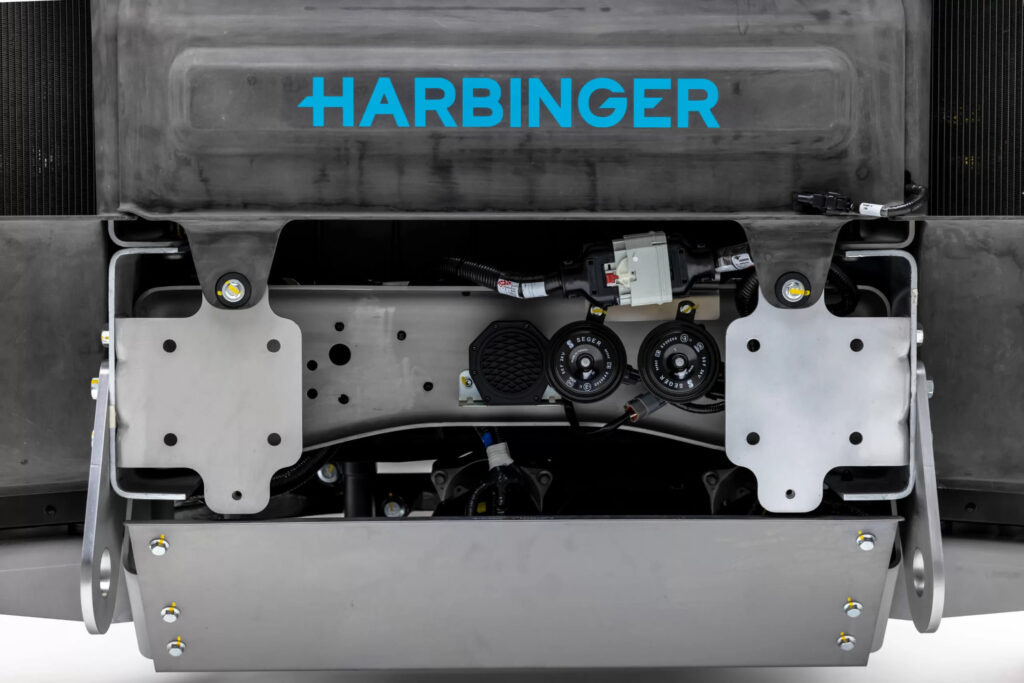

Harbinger’s stripped chassis, built in Garden Grove, California, serves as a foundational platform for a variety of vehicle types, including box trucks, delivery vans, emergency vehicles, and notably, RVs.

Designed with integrated systems such as the electric drivetrain, high-voltage battery, steering, and braking, the platform allows third-party body upfitters and manufacturers to customize units based on specific commercial or recreational use cases.

For RV industry professionals, Harbinger’s vertically integrated manufacturing model and in-house electric drivetrain system present a potentially more efficient path to EV adoption.

By managing core components in-house, the company aims to reduce production costs while maintaining quality—a factor that could support affordability and performance in future RV models transitioning to electric powertrains.

“Our ability to design and move our vehicle into production this quickly is a testament to the creativity and diligence of our world-class team,” said John Harris, Co-founder and CEO of Harbinger.

“Completing production of 100 chassis is an important achievement for Harbinger.”

The announcement arrives amid broader trends in the outdoor recreation and mobility sectors, where decarbonization and sustainability initiatives are increasingly influencing consumer preferences and regulatory compliance.

For RV manufacturers, the rise of medium-duty EV platforms may signal new opportunities—and potential infrastructure challenges—in fleet management, on-site charging capabilities, and eco-conscious branding.

Gilbert Passin, Harbinger’s Chief Production Officer, emphasized the importance of experience in developing their scalable approach.

“A lot of the experience that helped shape Harbinger’s manufacturing processes came from the experience our team brought from other EV manufacturers and automotive brands. We learned what didn’t work elsewhere, and we adopted what worked best.”

The company also announced an order book of 4,690 vehicles valued at approximately $500 million and recently secured a $100 million Series B1 funding round to support production scaling.

With additional hiring planned and expanded production capacity in development, Harbinger’s next phase may offer RV manufacturers and their suppliers a ready-made entry point into the evolving electric vehicle market.

Featured image by Harbinger via harbingermotors.com